In the rapidly evolving field of dental prosthetics, precision and versatility are paramount. Dental laboratories are constantly on the lookout for advanced technologies that can streamline the fabrication process while ensuring high-quality outcomes. One such groundbreaking technology is the wet milling machine, a versatile tool that has transformed the way dental prostheses are created. This blog post explores how wet milling machines, particularly the Dental Laboratorio-5T, are revolutionizing dental labs by enabling the fabrication of a wide range of materials, from titanium and zirconia to wax and PMMA blocks.

The Versatility of Wet Milling Machines

Wet milling machines are designed to handle a variety of materials, making them an indispensable tool in modern dental laboratories. Unlike traditional dry milling, wet milling uses a coolant to reduce heat and friction during the milling process. This not only extends the life of the milling tools but also ensures a superior surface finish on the prostheses. The ability to work with diverse materials such as titanium, zirconia, wax, and PMMA (Polymethyl Methacrylate) makes wet milling machines incredibly versatile.

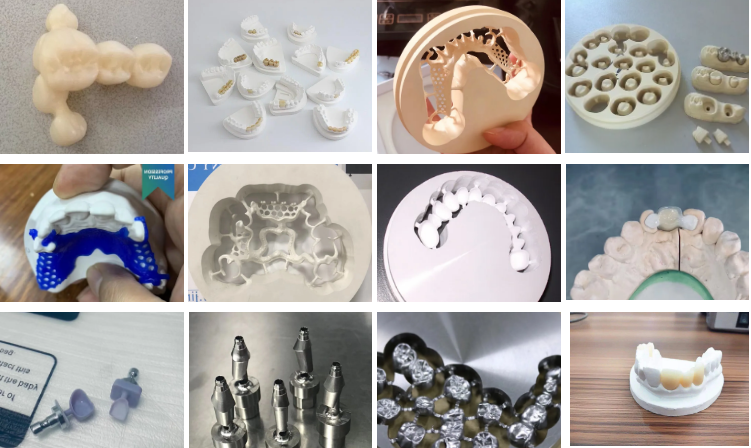

Fabricating a Wide Range of Materials

- Titanium Blocks:

- Titanium is renowned for its strength and biocompatibility, making it an ideal material for dental implants and prostheses. Wet milling titanium blocks helps in achieving precise dimensions and smooth surfaces, crucial for the longevity and fit of dental implants.

- Zirconia:

- Zirconia is favored for its aesthetic appeal and durability. Wet milling zirconia blocks allows for the creation of highly detailed and accurate dental restorations, such as crowns and bridges, with minimal risk of chipping or cracking.

- Wax:

- Wax patterns are essential for the lost-wax casting technique used in creating metal frameworks for dental prostheses. Wet milling ensures that wax models are produced with high precision, which is critical for the subsequent casting process.

- PMMA Blocks:

- PMMA is commonly used for temporary crowns and bridges due to its ease of manipulation and cost-effectiveness. Wet milling PMMA blocks results in prostheses with excellent surface finishes, reducing the need for additional polishing.

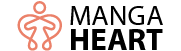

The Dental Laboratorio-5T: A Game Changer

For laboratories and technicians looking for a versatile wet and dry 2-in-1 unit dental milling machine, look no further than Dental Laboratorio, a dental lab supplies store that provides installation tutorials and manual guides for technician operations. The Dental Laboratorio-5T stands out as a state-of-the-art 5-axis dental milling system equipped with a touch screen for ease of use. This advanced machine is capable of handling a wide array of materials, making it a valuable asset for any dental lab.

Key Features of the Dental Laboratorio-5T

- 5-Axis Milling: The 5-axis capability allows for complex geometries and intricate details, essential for high-precision dental prosthetics.

- Touch Screen Interface: The user-friendly touch screen interface simplifies the operation, making it accessible even to those with minimal technical expertise.

- Dual Milling Modes: With both wet and dry milling capabilities, the Dental Laboratorio-5T can switch between different materials and requirements seamlessly.

- High Precision: The machine boasts a positioning accuracy of ±0.02 mm, ensuring that every prosthesis meets the highest standards of quality.

- Automatic Tool Changer: The fully automatic tool change and check system enhance efficiency and reduce downtime.

Enhancing Laboratory Efficiency

The integration of wet milling technology into dental laboratories significantly enhances operational efficiency. By reducing the need for manual finishing and minimizing material waste, laboratories can achieve faster turnaround times and higher throughput. Additionally, the versatility of the Dental Laboratorio-5T means that labs can consolidate their equipment, reducing the need for multiple machines and thereby optimizing space and resources.

The final step of polishing and finishing prosthetics in the sandblaster is crucial for achieving a flawless surface. The dental sandblaster creates an ideal environment for effectively purifying the prostheses, ensuring they are free from impurities and perfectly smooth. This process is essential for enhancing the durability and aesthetic appeal of dental restorations.

Conclusion

The advent of wet milling technology has marked a significant advancement in the field of dental prosthetics. Machines like the Dental Laboratorio-5T are at the forefront of this revolution, offering unparalleled versatility, precision, and efficiency. For dental laboratories aiming to stay ahead in a competitive market, investing in such advanced wet milling technology is not just an option but a necessity.

By embracing these innovations, dental technicians and laboratories can ensure they are equipped to meet the diverse needs of their clients, delivering high-quality dental prostheses that stand the test of time. Whether it’s titanium, zirconia, wax, or PMMA, the Dental Laboratorio-5T wet milling machine is a testament to the incredible possibilities that modern dental technology holds.